32 265 19 84

More and more goods are more and more often sold by weight, multiplying the load’s tonnage by the determined price of a weight unit. In the case of wholesaling directly at the manufacturer’s, distributor’s, goods are weighed after loading onto the transporting vehicle, bye means of a car scales, more specifically – sales control system.

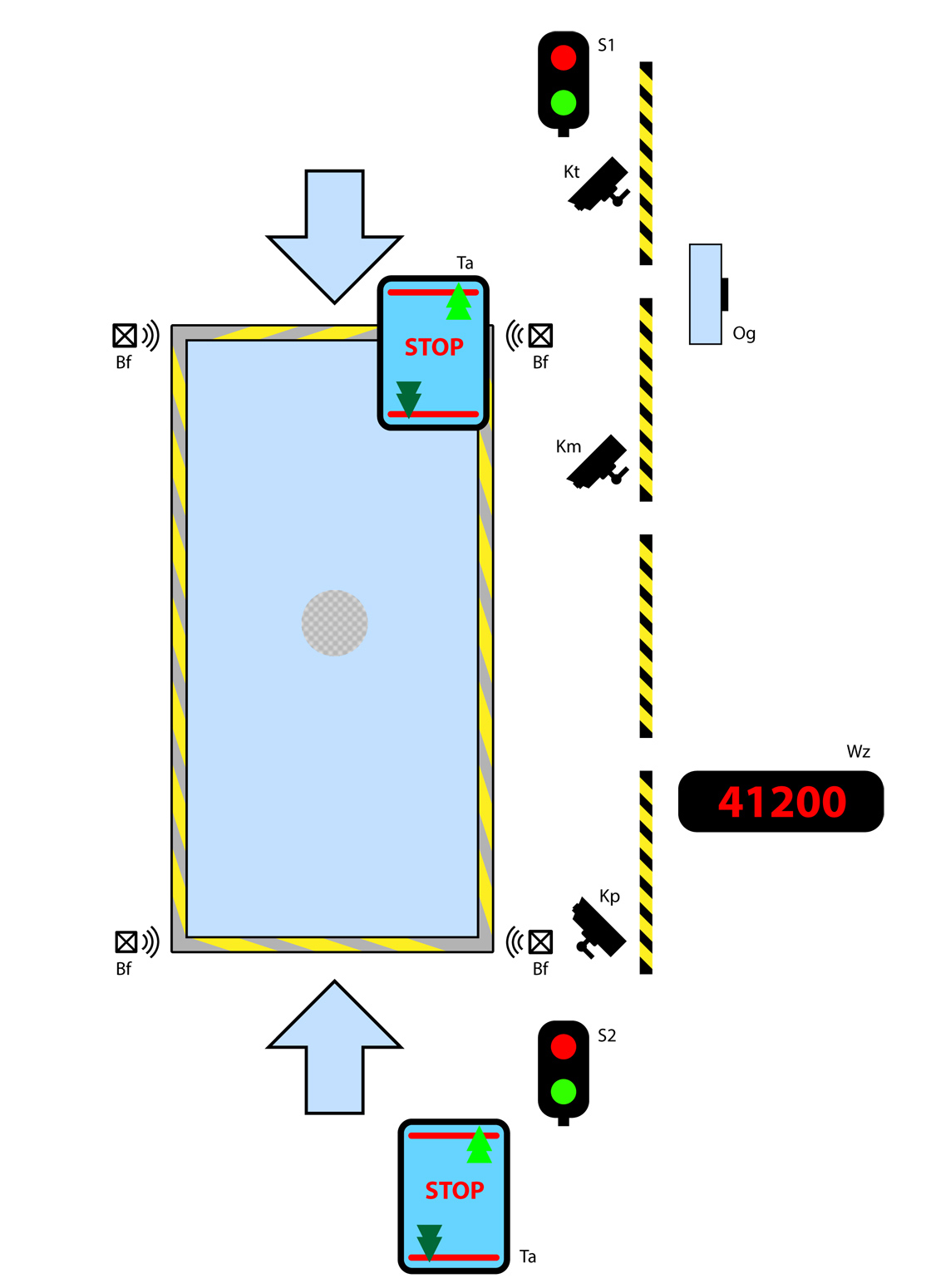

The system consists of closed-circuit video cameras and proper additional lighting of the scales area as well as many limiting sensors. Automation of the process of weighing goods on trucks makes loading more efficient by shortening the weighing time. One of the solutions improving the process is monitoring recognizing the licence plate as well as a system of signal lights within the weighing ramp, synoptic boards and an ultrasonic sensor.

A number of protections and control sensors enables precise weighing and elimination, or at least minimization, of the risk of errors in weight display.

The truck along with the load approaches the weighing platform, where signal lights direct particular stages of rolling onto the scales, location of the vehicle on the ramp by displaying commands on the synoptic board and a sound signal confirming proper location of the vehicle on the platform. Images from video cameras, both the ones recognizing licence plates and load, are automatically saved as documentation of the weighing process; an additional advantage of the sales control system is association with software generating inventory issue documents (WZ) which is the basis for sales settlements.

Weighing process automated in such a way enables self-service without the need to engage a scales operator as well as sales and remote registration through data transmission from the scales to the sales service point, regardless of the actual distance from the car scales.